Hi companero

glad, you’re happy but im not 100% following along. Probably me that’s being think here (not the first time).

380 ÷ (3.1415 x 1.25 x 1.25) x 2.4 = 185.8

185.8/1100 = 0.1689

As I understand the original, this is Mach 0.17 (a velocity). I’m not sure about what that means for 1.75" pipe… As i said, I’m no doubt missing an important point here, but as you were keen on grokking the whole thing, I thought I’d raise this again.

Cheers

EDIT

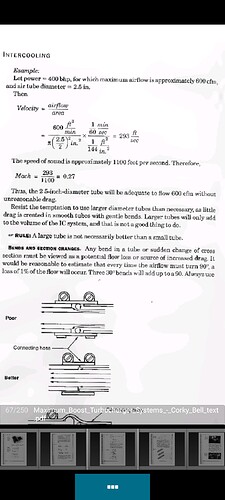

looking again at the book snippet you posted. The Mach number seems important as it directly relates to the drag in the pipe. Higher Mach number will give higher drag. The 2 diagrams at the bottom seem to be talking about that too - one shows turbulent flow inside the pipe (presumably the Mach number was too high) and the second shows laminar flow. It feels to me like the author is saying that as the Mach number is low (0.27) the 2.5 inch pipe is fine to handle airflow of 600 cubic feet / minute.

If you reduce the airflow from 600 → 380 but want to keep the Mach number about the same, we can reduce the pipe diameter, but it’s not so straightforward. We have to solve this equation for the pipe diameter:

Airflow (CFM)

__________________________ x 2.4 = 293 (=Mach 0.27)

π x (1/2 x pipe diameter)^2

We know the airflow is 380, so in other words what pipe diameter solves this equation?:

380

_____________________ x 2.4 = 293

π x (1/2 x pipe diameter)^2

a bit of messing about and we get:

380

______ x 2.4 = (1/2 x pipe diameter)^2

π x 293

or finally that the pipe diameter for an airflow of 380 CFM and a Mach number of 0.27 is:

pipe diameter = 2 x square root ( 2.4 x 380 ÷ (π x 293) )

pipe diameter = 2 x 0.995 = 1.99 inches.

so a 2 inch pipe would give you the same drag for an airflow of 380 CFM as a 2.5 inch pipe would for an airflow of 600 CFM.

I might be way off base here, in which case I’ll come back and delete all the unnecessary crap. But thought I’d post it up in case it’s still helpful